Rice has been used in beer brewing for many decades. For many years, it was considered as a cheap way for the big commercial breweries to pad out their beer. In more recent years however, craft and home brewers have started to discover that rice is actually a delicious ingredient, that adds to the beer in it’s own unique way. Read on to see how to brew a rice lager.

Let’s Get Brewing

Let’s take a look at the brew process. This is for a starting volume of 25 litres water, using an electric all in one brewing system.

I’ll list the recipe details at the bottom for reference.

Brew a Rice Lager

As always, we need to start in the grain storage room. Here, I’ve weighed out the grains, and they’re being milled at 1.1mm in the MattMill Master. It’s a relatively small grain load, as there is a very high percentage of rice to follow.

Then the flaked rice gets weighed out. An important ingredient when brewing rice beer….

Flaked rice is one of the easiest ways to use rice in a beer recipe. It has already been gelatinised for you, then dried and flaked. This means that it will easily re-hydrate, and it’s starches will become readily available for the mash enzymes to convert to fermentable sugars.

You can also use rice grains. This will give you a greater range of rice types to use, and each variety gives a slightly different taste to the finished beer. To use grained rice, you will need to do a cereal mash, or alternately, cook the rice for an extended period to gelatinise the starches. Maybe I’ll show those another day…

Water Profile

The water profile for rice lager is a relatively light one, and I use a ‘Yellow Balanced’ profile for mine.

Below are the salts and minerals.

Once the 25 litres of water is heated to ‘doughing in’ temperature, I add the malt pipe.

Then the grains are pour in. You can clearly see the high percentage of rice flakes being used.

Start the mash

With the grains in, the filters are put on and the mash is started. As soon as the mash water reaches 40°c, the grains are doughed in. Then I raise the temperature to 67°c for 60 minutes. After which I mash out at 77°c for 5 minutes.

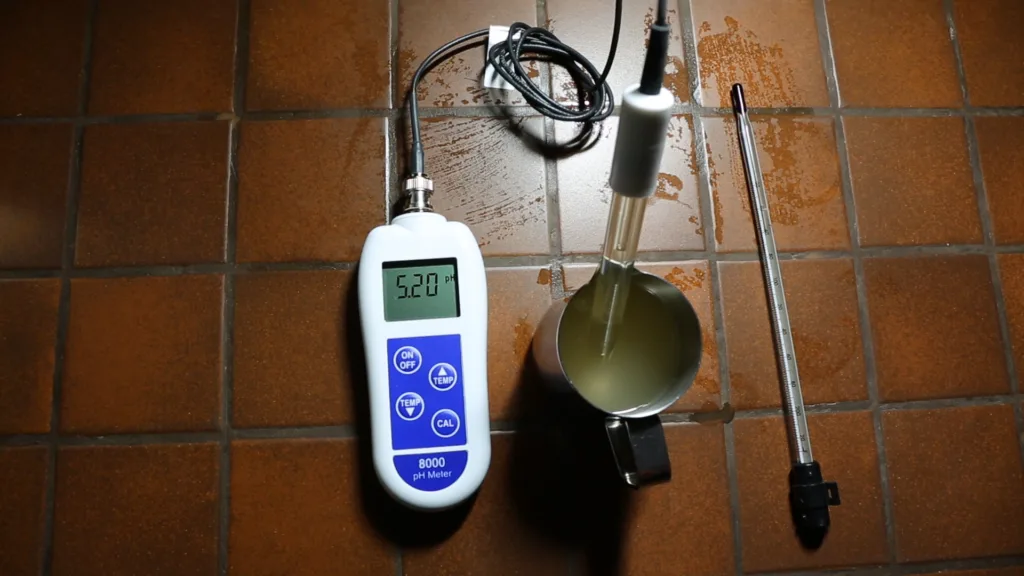

Having raised the mash heat to saccharification temperatures, the ph test shows 5.20, which is perfect for this.

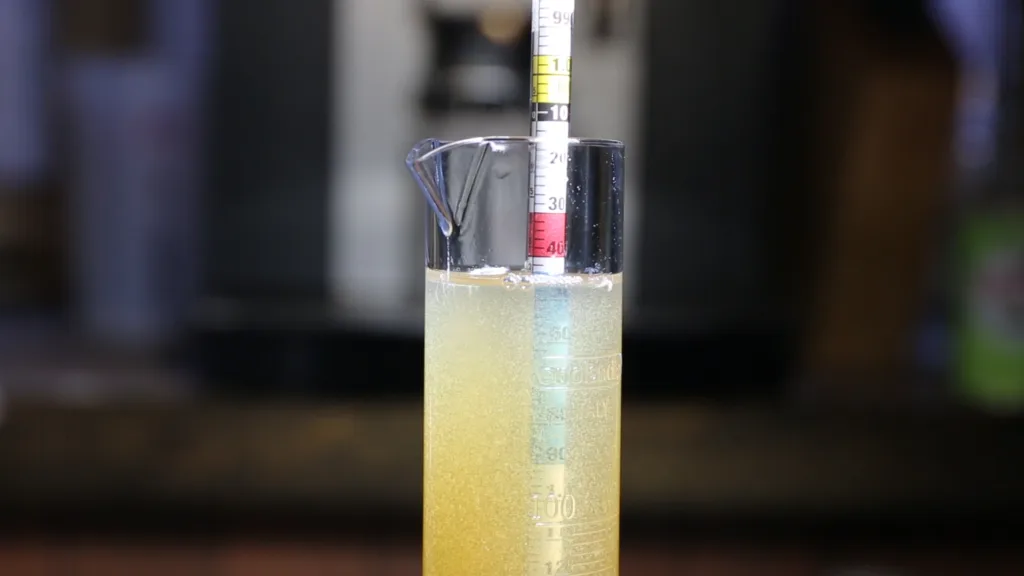

After 60 minutes mash, I perform an iodine test. The iodine stays yellow, showing that there is no starch left in the wort. The mash temperature can be raised to 77°c for mashing out.

Whilst the temperature is rising toward boiling, I measure out the hops. Saaz for 60 minutes boil, and Galaxy for the whirlpool.

The Boil

With a rolling boil, the Saaz is added.

After 60 minutes boil, the immersion chiller is put in, and the wort temperature is lowered to 74°c for the ‘whirlpool’. The galaxy hops pellets are added for a fifteen minutes whirlpool at 74°c.

During the 15 minutes whirlpool, I am re-hydrating the Mangrove Jacks M76 Bavarian Lager yeast.

With the wort cooled, a gravity check shows an Original Gravity of 1.044

Transfer

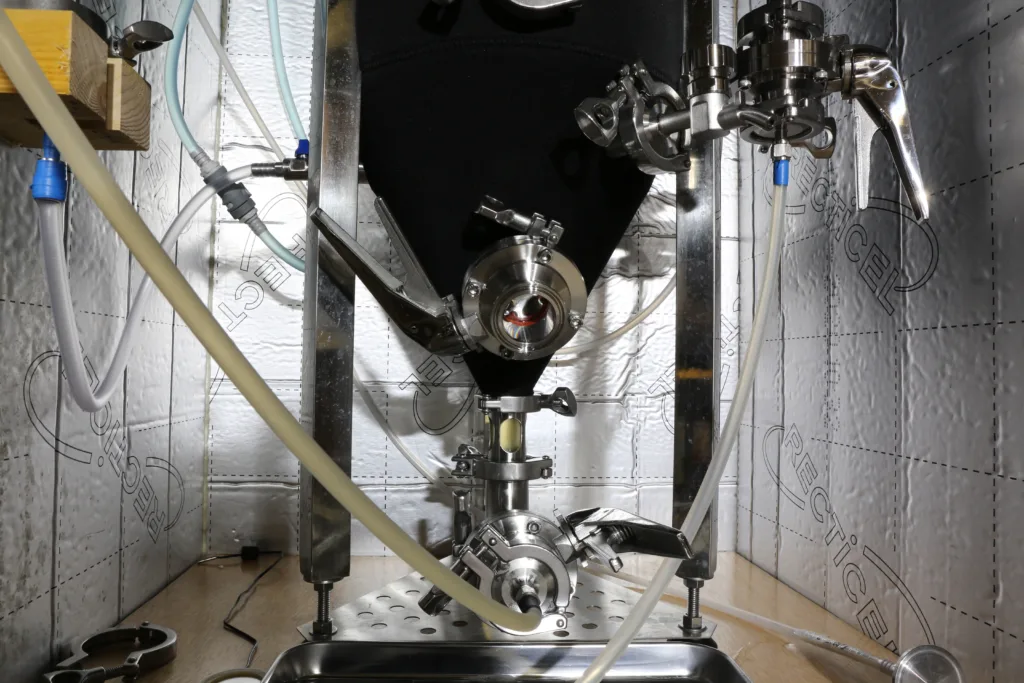

The rice lager is fermented in my temperature controlled keg fermenter. The re-hydrated yeast is poured in first.

I then gravity transfer the wort into the keg. The fermentation keg I am using has full temperature control, with glycol cooling. It also has a heat mat that wraps around the base.

Fermentation

The Rice lager ferments at 10°c for 3 weeks, and then a diacetal rest for 7 days at 18°c.

After a total of four weeks fermentation, the lager’s gravity transferred to the unitank, where I chill it to 3 °c. This is where I dry hop it cold for 2 days. I find this method brings out a fresher dry hop flavour, with less of the resin and grassy hop characteristics coming forward.

I always run a positive gas flow of CO2 when adding dry hops, to stop air ingress into the tank.

After two days of dry hopping, I drained the hops from the unitank. At this point I used gelatin finings to clear the yeast. I then carbonated to a bottling volume of 2.4 volumes CO2.

Using the Blichmann beer gun, I’ve bottled the rice lager, and then placed in our cool storage area, where it will lager for a few weeks.

After a few weeks lagering, the beer is ready to drink. A warm sunny day beckons bringing out the Rice Lager as a break from mowing the lawns.

That’s all there is to brew a rice lager. So how does it taste?

The Tasting

Upon pouring, this beer has a large foamy white head that lasts and lasts. This is largely due to the rice. I believe.

The aroma coming off the top is of Cascade hops. It’s a lovely smell of fresh citrus that is unmistakably cascade.

Taking a sip of this lager gives an immediate taste of cascade, which then gives way to a clean fresh and crisp lager. The body is not thin, which is what many people associate to using rice. Instead, the rice gives a unique body and mouthfeel, a feeling of smoothness, whilst still strangely remaining crisp. Unusual.

This beer attenuated well during fermentation, and yet there is still a certain amount of sweetness. This I again attribute to the rice.

All in all. this is one of our favorite summer beers, and is rarely out of stock for us here on the farm. I can’t see any reason to change this recipe in the near future.

Rice Lager Recipe Ingredients

Fermentables

2000 g Pale Malt (54.8%)

1500 g Flaked Rice (41.1%)

100g Dark Munich (2.7%)

50g Honey Malt (1.4%)

Hops

22 g Saaz @ 60 minutes (14.9 IBU)

15 g Galaxy @ Whirlpool (5.2 IBU)

25g Cascade @ Dry Hop

Yeast

Mangrove Jacks M76 Bavarian Lager

Water

Ca: 49 ppm

SO4: 75 ppm

Cl: 61 ppm

% Alc Vol

4.5 %

If you’d like to watch the full brewday on YouTube then click here.